SKU #10524

Trapezklingen (abgerundet)

Die Slice 10524 Trapezklingen (abgerundet) sind ideal für manuelle Arbeiten, wie das Entgraten von Spritzgussteilen aus Kunststoff, oder die Verwendung mit Werkzeugen von Drittanbietern. Diese Klingen wurden von Slice entwickelt, bevor wir unsere eigene Produktlinie von Cuttermessern herausgebracht haben. Natürlich legen wir unseren Kunden nahe, die Cuttermesser von Slice auszuprobieren. Sollten Sie jedoch nach einer größeren Klinge für den manuellen Einsatz suchen, empfehlen wir die 10524 Klinge; sie wird aus Hochleistungskeramik hergestellt, welche funkenfrei, unmagnetisch, chemisch neutral, hitzestabil bis 1600°C und rostfrei ist. Passende Werkzeuge sind beispielsweise: Lenox 20366SRK1, Alltrade 150003 Auto-Load, Wiss WKAR1 mit automatischem Klingenrückzug, IRWIN 2088600 und Milwaukee Fastback 48-22-1901.

- Klingentyp: abgerundet, austauschbar

- 2 doppelseitige Klingen pro Packung

- Sicherheitsklinge, die 11x länger scharf bleibt

- Minimiertes Verletzungsrisiko, geringere Kosten

- Funkenfrei, nicht leitend, unmagnetisch

- Chemisch neutral, rostet nicht

- Weniger Klingenwechsel = weniger Verletzungen

- Art.-Nr. 10524

Produktdetails

Produktdetails

Cutting Depth:

Material: zirconium oxide

Dimensions: L x W x H

Weight: 0.016 kgKompatible Produkte

Videos

-

Blade Replacement on Metal-Handle Utility Knives

-

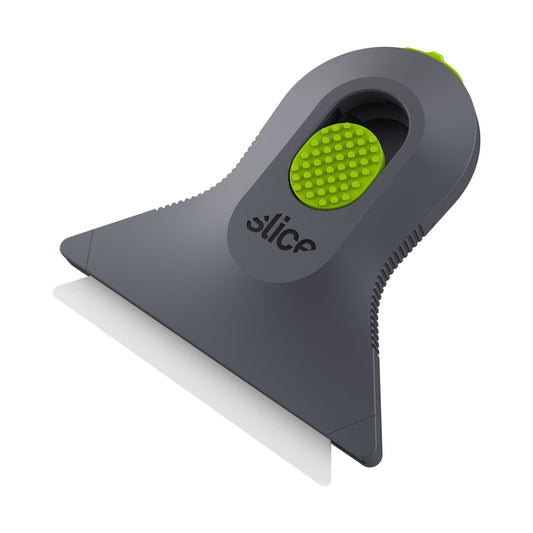

Blade Replacement on the 10594 Manual Mini Scraper

FAQ - Häufige Fragen

What Can I Use Ceramic Utility Blades For?

Slice®’s thicker, more durable ceramic blades do not flex in the same way as metal, so they’re not ideal for any application that exerts a side load or requires the blade to bend. But typical uses, such as hand trimming solder from metal parts or plastic flash from injection-molded products are just as easy—and much safer—with Slice utility blades.

What’s the Advantage of Ceramic Blades?

For that reason, the best utility blades to reduce hand and finger injuries are Slice blades. Our proprietary grind creates an edge that cuts materials effectively and is safe to the touch. Slice blades also hold their cutting edge, on average, 11.2 times longer than steel. This means fewer blade replacements and therefore fewer opportunities for injury.

Other advantages of advanced ceramics come from the properties of our ceramic material. Zirconium oxide is chemically inert, non-sparking and non-magnetic. It can be heated up to 1600 degrees Celsius and requires no special oil or lubricant coating to maintain sharpness.