Loved by Everyone Who Wants an Easier Life

-

These are the best, most convenient, most well designed, useful products I have bought in several years. I will be giving all of them to all of my friends for stocking stuffers at Christmas in 2023. They have quickly become indispensable for me. Excellent customer service as well.

Mary Lynn B.

-

I wish I had these many years ago... they all work so well to open all kinds of gnarly packages! High-quality, and a pleasure to use!

Thomas K.

-

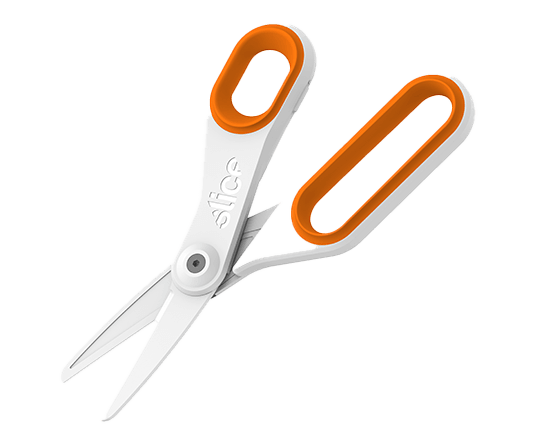

"I really think this is the best product I have purchased recently. I love the box cutter and smaller one to open those darn plastic clam shell sealed things"

Sherie E.

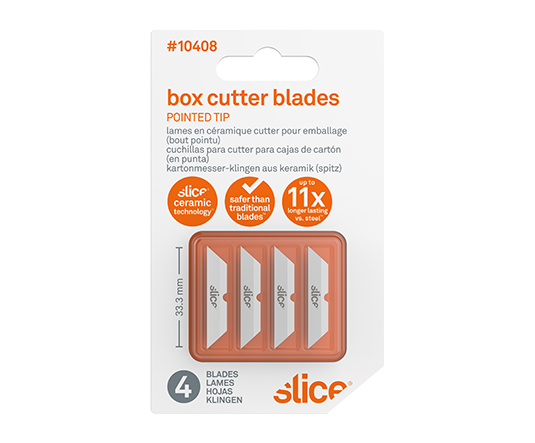

Our Safety Is in the Blade

Our tools are safer than traditional knives because we’ve redesigned the blade itself. We refused to accept the conventional thinking that a cutting tool must be dangerous - so we created a range of highly effective safety tools with finger-friendly blades.

Learn MoreExperience Safety, Redefined

Founded With a Mission

Slice was founded by TJ Scimone in 2008 to help fund long-term care for his autistic son, and we donate a minimum 1% of all corporate profits to global research programs that support families and individuals living with autism.