Ceramic Blades: Everything you Need to Know

The Properties of Ceramic Blades

First, let’s talk about what we mean by ceramics, because Slice® ceramics are not the fragile ceramics of popular imagination. They’re actually part of a more recent category of material known variously as advanced ceramics, fine ceramics, or engineered ceramics. The material is composed of 100 percent zirconium oxide. Developed through the advances in ceramic research of the 1950s, zirconium oxide has many useful properties.

A Versatile Material

Zirconium oxide has many advantages over steel, especially for industrial applications. Unlike metal, a zirconium oxide utility blade is chemically inert. This means no chance of chemical reactions while you cut, as well as a strong defense against harmful bacteria. Ceramic never rusts, which means it doesn’t require the same oils and lubricants used on metal blades to prevent premature rusting.

Industries as varied as pulp and paper and aerospace benefit from the use of engineered ceramic utility blades because of these inherent properties:

- Non-magnetic

- Non-conductive

- Non-sparking

- Safe up to 1600 degrees Celsius

- Chemically inert and non-contaminating

- Non-reactive: impervious to acids and salt

- Non-porous and chemically resistant

- Oil and lubricant free

- Never rusts

Hard as Nails (Harder, Actually)

When customers used to traditional blades try Slice tools for the first time, they’re comparing two very different cutting experiences. There are important manufacturing differences between a Slice ceramic blade vs steel, due to the different properties of these materials. Most ceramic blade manufacturers copy metal-blade manufacturing processes because that’s what people are familiar with. But these manufacturing processes were developed for metal and its particular properties. The primary difference between advanced ceramics and metal is hardness.

Zirconium oxide is much harder than even the hardest steel. Why is hardness important? Because steel’s relative softness is the reason it’s sharpened to unsafe levels; it dulls too quickly. Unfortunately for safety, other ceramic blade manufacturers didn’t take this main difference into account and instead reproduced the dangerously-sharp edge of a metal blade, even though it’s not necessary. Zirconium oxide’s hardness allowed Slice to develop a patent-pending manufacturing process that creates a finger-friendly® edge.

Slice’s Finger-Friendly Ceramic Blade Edge

While other companies create extremely sharp ceramic blade knives, Slice was primarily interested in safety. We asked: What level of sharpness does it actually take to cut most materials? It turns out that the only reason steel blades are dangerously sharp is because steel dulls so quickly. Manufacturers need to produce overly sharp blades just to give them a reasonable working lifespan. This workaround sacrifices safety for productivity. Because ceramics dull so slowly, they don’t need that workaround.

The above chart demonstrates that, while Slice blades don’t start out as sharp as steel (because they don’t have to), they outlast steel by an average factor of 11.2. This is a product of zirconium oxide’s extreme hardness and our sturdy blade edge design.

While the inherent properties of advanced ceramics were first attractive to kitchen knife manufacturers and later utility tool makers, Slice was the first to take advantage of zirconia’s hardness to develop a grind that is actually safer to touch. That’s what makes a Slice ceramic blade different from any other. So different, in fact, that our proprietary manufacturing method is pending patent.

What Do We Mean by Finger Friendly?

Finger friendly simply means that Slice blades are safer to touch and handle than traditional blades. You can pick up Slice replacement blades without fear of accidental injury. Compared with typical blades, for example, our utility blades are unlikely to cut your skin because they require much more force to do so. As shown below, you can run a Slice blade over a balloon’s surface and the balloon will remain intact. That’s simply not the case for other blades.

If Slice Blades Cut Other Materials Effectively, How Do They Resist Skin?

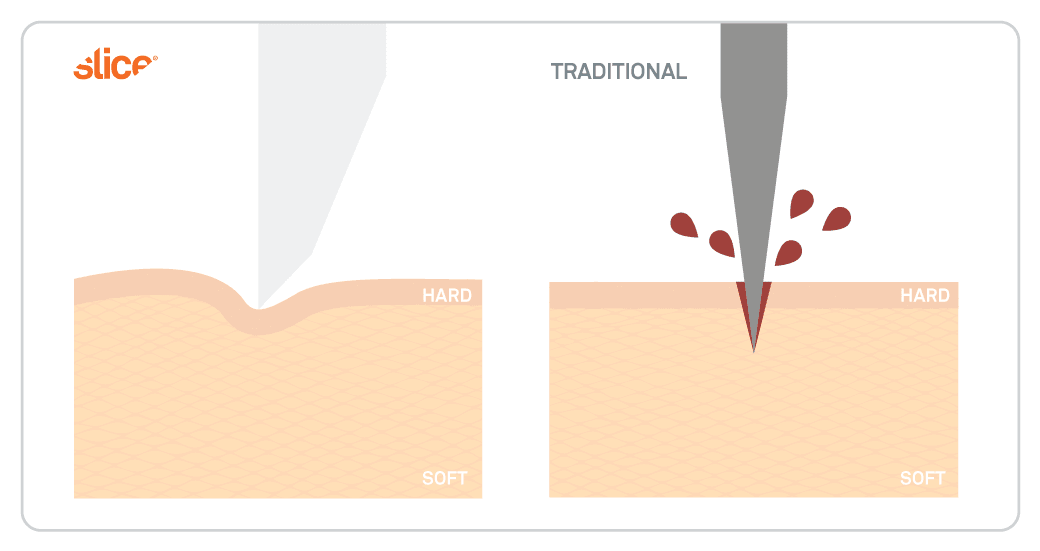

Slice engineers first looked at why standard blades pierce the skin so easily. Not only are their edges overly sharp, but the blade itself is quite narrow. This means it requires little force to pierce the skin.

The part of a blade that is intended to cut is known as the initial cutting zone. By grinding our blades with two different angles and using a wider blade overall, Slice made the initial cutting zone (the potentially dangerous portion of the blade) much smaller.

Finally, we took into account the properties of skin, which is harder on the surface, but pliable as a whole. Our grind dissipates the pressure on skin, making it harder to penetrate.

Can Slice Ceramic Blades Cut Your Skin?

Although they are much safer than traditional knives, Slice blades are capable of cutting skin; they’re knives after all! If you try to cut your skin with our blades, you will likely succeed. Our blade grind vastly cuts down on accidental lacerations, but the blades are still effective and therefore no match for the human determination to cut something.

Because our blades are so different from any you’ve seen before, we recommend that you touch the edge to understand just how much safer they are compared with standard blades. You’ll instantly feel the difference and understand why Slice safety blades are a wise choice to reduce injuries. Many industrial safety officers no longer require the use of safety gloves when workers use Slice blades.

Slice Safety Blade Categories

At Slice, our research and development is a continuous cycle. We’re in touch with safety experts across many industries to develop safer tools and reduce costs. Below are some of our blade categories.

Double-Sided Ceramic Replacement Blades

Slice manufactures a variety of replacement blades, including those that will look most familiar: ceramic utility blades, utility knife blades, box cutter blades and industrial blades. Choose from rounded or pointed tips, with the assurance that our blades last an average of 11.2 times longer than steel blades. This means you won’t need to replace your blade any time soon. As well, all these blades have two functional ends so that when one end does finally wear down, the user can reverse the blade for a fresh end that will last another 11.2 times longer than steel.

We design our blades to fit in as many Slice handles as possible, making them versatile investments.

Craft Blades

Slice craft blades fit our various precision handles, including our craft knives and scalpels. These one-sided specialty blades are ideal for manufacturers, artists, or crafters looking to reduce injuries.

Micro-Ceramic Blades

Slice micro-ceramic blades are just as hard as our larger blades and include the same finger-friendly edge, but they also feature minimal protrusion from the tool. This adds another level of safety, as the limited blade exposure is much less likely to cut skin. Despite this, the blades are still extremely hard and can handle all manner of thin materials, from paper to hard clamshell packaging. Slice offers three different tools with micro-ceramic blades: the 00200 Safety Cutter, the 00116 Precision Cutter, and the 10583 Safety Cutter Ring.

Scissors

Slice extends its finger-friendly grind to three different models of ceramic scissors, creating tools that are safe and very effective. These compact and lightweight safety scissors work well in lab settings, industrial settings, or with anyone who has fine motor challenges. Most cuts can be accomplished with rounded-tip scissors, but we also make pointed scissors for cuts that must be initiated with a puncture.