セラミック替刃(ラウンド刃先ユーティリティ)

SKU #10524

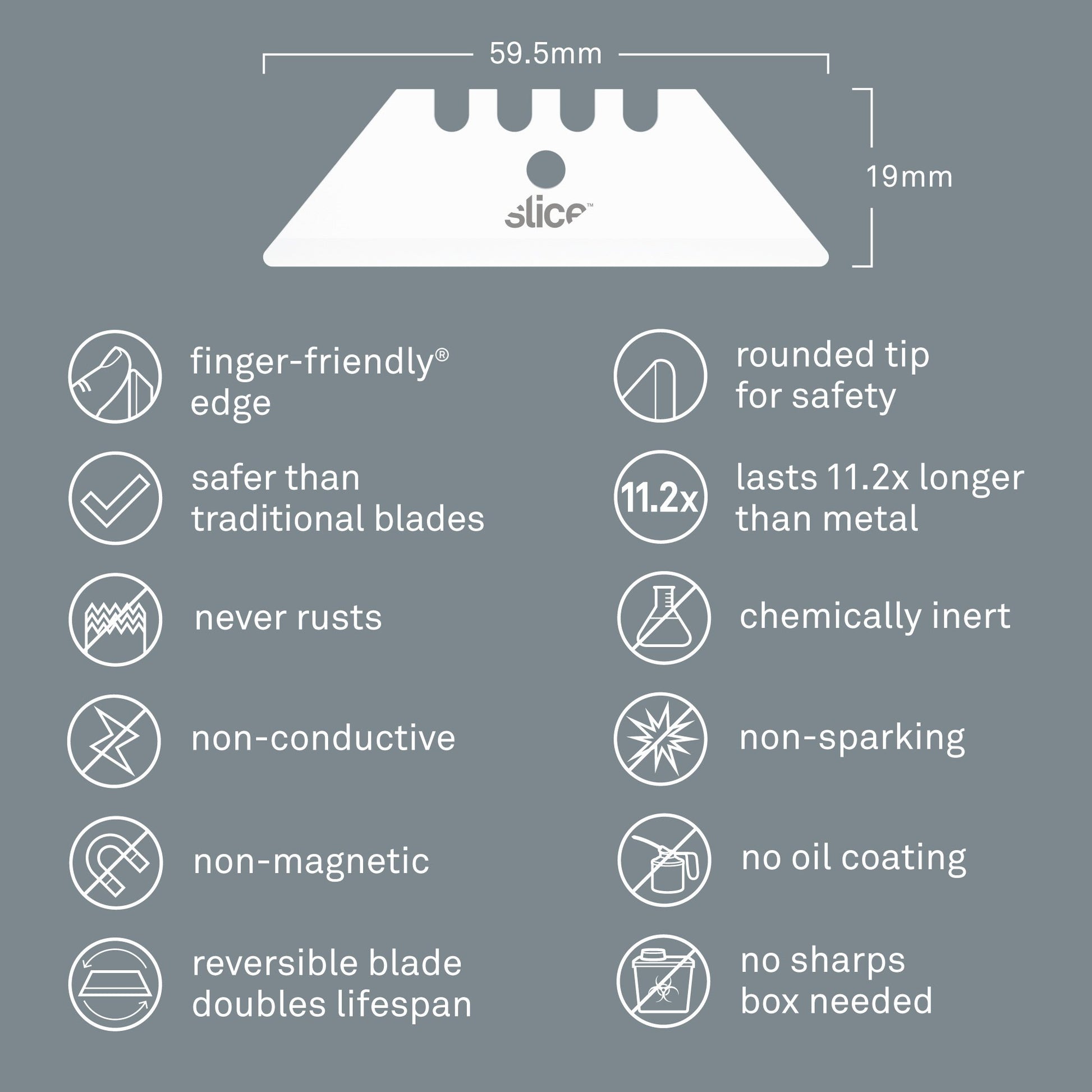

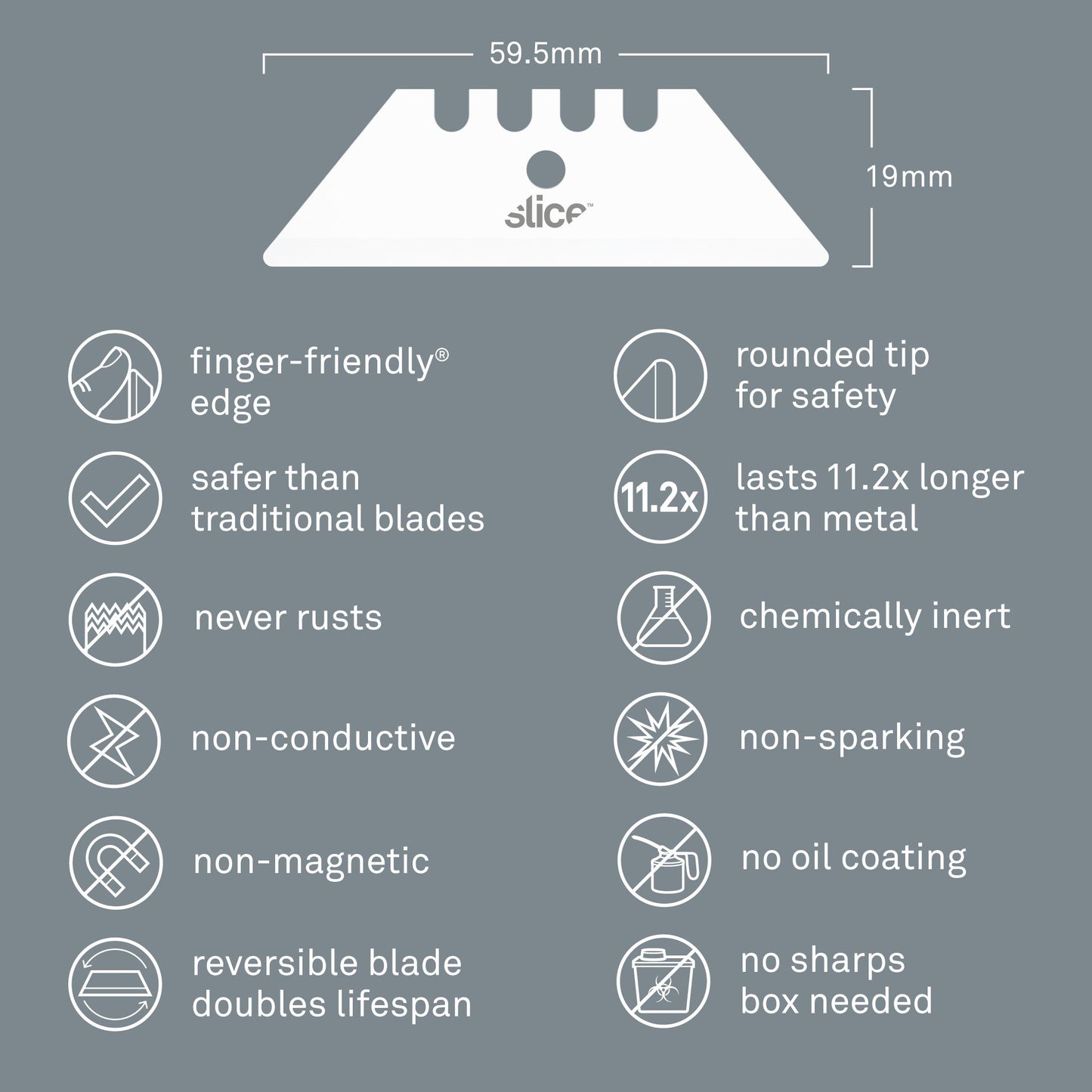

Slice® 10524 セラミック替刃(ラウンド刃先ユーティリティ)は、10490、10491メタルハンドルユーティリティナイフに最適な替刃です。先進のセラミックを使用した、10524 セラミック替刃(ラウンド刃先ユーティリティ)は、非発火性、非磁性、化学的不活性で、オイルコーティング不要です。また錆びることもありません。酸化ジルコニウム(100%)製で頑丈な、finger-friendly®(指にやさしい)セラミック安全刃は、固い素材にも対応でき、耐摩耗性にも優れています。従来の金属刃に比べて、11倍長持ちします。刃先が丸くなっていることでケガを軽減し、また結果として、コストの削減にもつながります。

- 刃の種類:ラウンド刃先

- 従来の金属刃より安全

- finger-friendly®(指にやさしい)刃で効率よく裁断

- 金属刃に比べ耐摩耗性が11.2倍

- 刃の交換回数が減る=怪我が減る

- ケガの軽減、コストの削減

- 非発火性、非電導性、非磁性

- 化学的不活性、錆びない

- オイルや潤滑油が不要

- 一般廃棄物

- 100%リサイクル可能

- 刃の耐熱温度:-40°C ~ 1600°C

- 適合する持ち手:10490、10491、10496、10497、10582、10590、10594

- 2枚入り(両側の刃先が使用できます)

- SKU #10524

Product Specifications

Product Specifications

Cutting Depth:

Material: zirconium oxide

Dimensions: L x W x H

Weight: 0.04 lb

Compatible Products

Related Products

FAQ

What Can I Use Ceramic Utility Blades For?

Use these blades for the same applications as you would use a regular utility blade, and more. The properties of advanced ceramics ensure that your blade is non-sparking, chemically inert, autoclave-friendly, and never rusts.

Slice®’s thicker, more durable ceramic blades do not flex in the same way as metal, so they’re not ideal for any application that exerts a side load or requires the blade to bend. But typical uses, such as hand trimming solder from metal parts or plastic flash from injection-molded products are just as easy—and much safer—with Slice utility blades.

Slice®’s thicker, more durable ceramic blades do not flex in the same way as metal, so they’re not ideal for any application that exerts a side load or requires the blade to bend. But typical uses, such as hand trimming solder from metal parts or plastic flash from injection-molded products are just as easy—and much safer—with Slice utility blades.

What’s the Advantage of Ceramic Blades?

Until recently, utility blade types included only steel. The sole customizable option was to choose a different handle. Slice added ceramics to the market. Since then, other companies have started manufacturing ceramic utility blades, but none offer Slice’s finger-friendly® safety edge.

For that reason, the best utility blades to reduce hand and finger injuries are Slice blades. Our proprietary grind creates an edge that cuts materials effectively and is safe to the touch. Slice blades also hold their cutting edge, on average, 11.2 times longer than steel. This means fewer blade replacements and therefore fewer opportunities for injury.

Other advantages of advanced ceramics come from the properties of our ceramic material. Zirconium oxide is chemically inert, non-sparking and non-magnetic. It can be heated up to 1600 degrees Celsius and requires no special oil or lubricant coating to maintain sharpness.

For that reason, the best utility blades to reduce hand and finger injuries are Slice blades. Our proprietary grind creates an edge that cuts materials effectively and is safe to the touch. Slice blades also hold their cutting edge, on average, 11.2 times longer than steel. This means fewer blade replacements and therefore fewer opportunities for injury.

Other advantages of advanced ceramics come from the properties of our ceramic material. Zirconium oxide is chemically inert, non-sparking and non-magnetic. It can be heated up to 1600 degrees Celsius and requires no special oil or lubricant coating to maintain sharpness.

Does Slice Make a Ceramic Utility Knife?

Yes! We make a whole line of utility knives with different blade retraction options, including manual retraction (with multiple fixed-position cutting depth options), auto-retractable, and smart-retracting handles. Each ceramic utility knife offers different choices to account for personal preferences and varying safety regulations.

What Handles Will This Utility Blade Fit?

The trapezoidal utility blades that Slice makes (that is, the 10523, 10524, 10525 series) are all compatible with our metal-handle utility knives. These knives include the 10490 Manual Metal-Handle Utility Knife and the 10491 Auto-Retractable Metal-Handle Utility Knife. Both these knives are ambidextrous and feature a large, sturdy handle. The manual version locks in place, offering three preset cutting depths, while the auto-retractable version retracts on its own, as soon as the user releases the slider.