Ostrza trapezowe (Ząbkowane)

SKU #10523

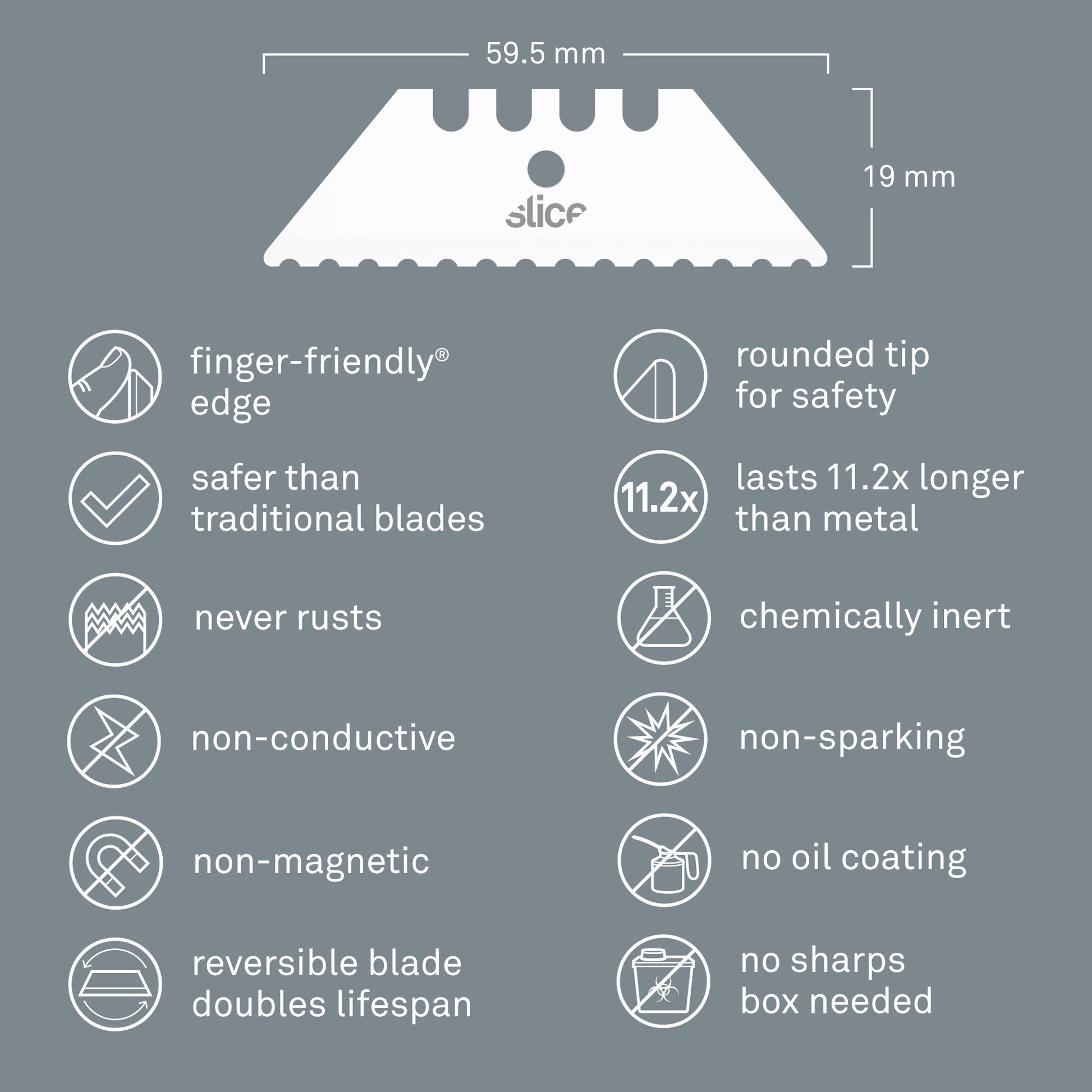

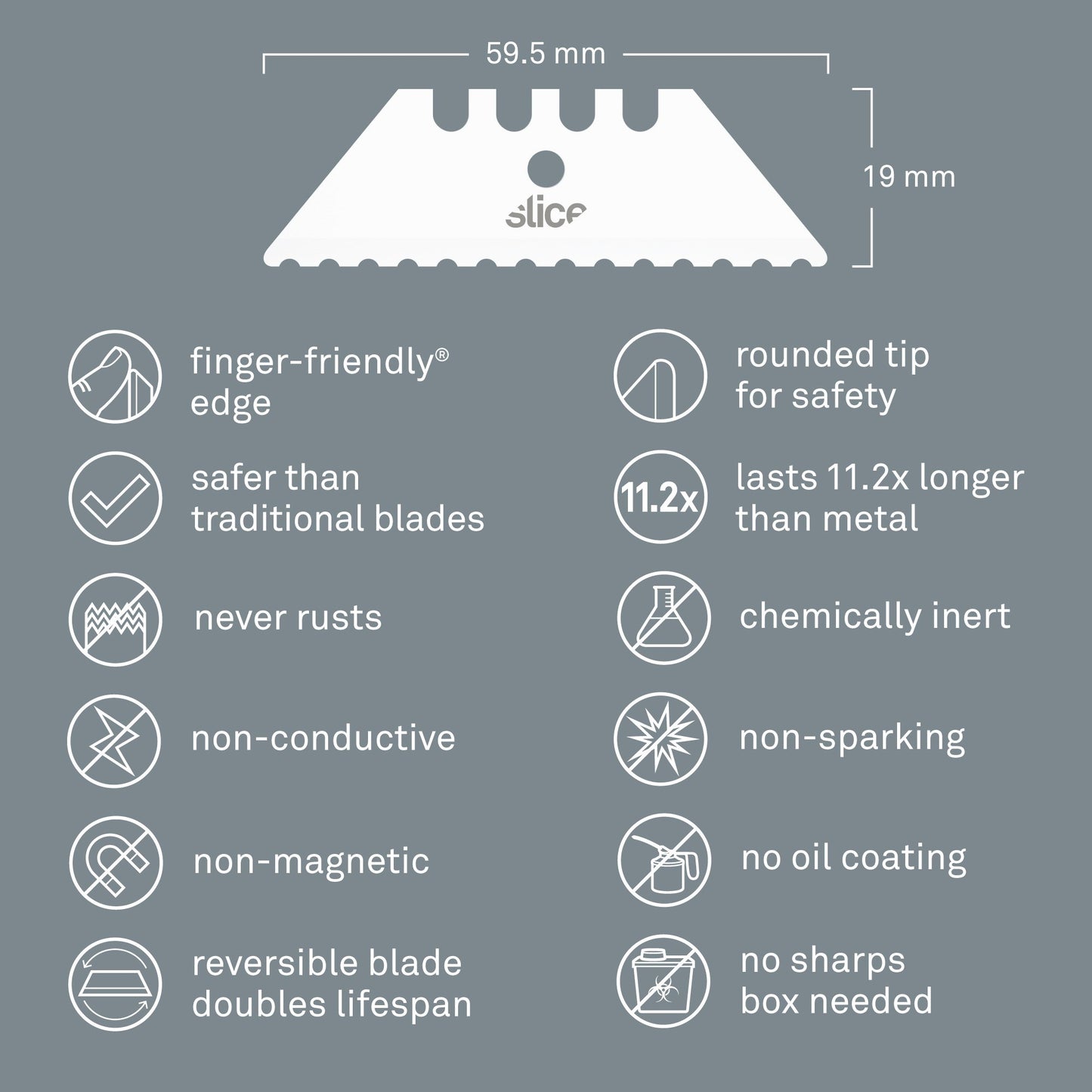

Ząbkowane ostrza trapezowe Slice® 10523 wyróżniają się nawet do 11 razy dłuższą żywotnością niż ostrza metalowe i posiadają zaprojektowaną przez nas bezpieczną w dotyku krawędź finger-friendly®. Takie połączenie przekłada się na rzadszą wymianę ostrza oraz zmniejsza liczbę skaleczeń, co znacząco usprawnia przebieg pracy. Ponadto, nie wymagają smarowania ani konserwacji i nigdy nie rdzewieją. Ostrze trapezowe 10523 jest szczególnie efektywne we wszystkich sytuacjach wymagających piłowania. Postaw na maksimum bezpieczeństwa i gwarancję skutecznego cięcia.

- Rodzaj ostrza: ząbkowane

- Bezpieczniejsze niż tradycyjne ostrza

- Efektywnie tnącą krawędź finger-friendly®

- Nawet do 11.2 razy dłuższa żywotność niż w przypadku ostrzy metalowych

- Rzadsza zmiana ostrza = mniej skaleczeń

- Mniej skaleczeń i mniej wydatków

- Nieiskrzące, nieprzewodzące prądu elektrycznego i niemagnetyczne

- Chemicznie obojętne, nigdy nie rdzewieją

- Nie wymagają smarowania

- Nie wymagają utylizacji w pojemnikach na zużyte ostrza

- W pełni recyklingowalne

- Bezpieczne w użytku do 1600°C

- Kompatybilne rękojeści: 10479, 10490, 10491, 10493, 10496, 10497, 10582, 10590, 10594

- W opakowaniu dwa ostrza

- SKU# 10523

Great for:

- Tough, textured materials that require a sawing action to cut

- Thicker materials, such as insulation and foam

- Tough strands that make up twine and rope

Product Specifications

Product Specifications

Cutting Depth:

Material: zirconium oxide

Dimensions: L x W x H

Weight: 0.04 lb

Videos

-

Blade Replacement on Metal-Handle Utility Knives

-

Blade Replacement on the 10594 Manual Mini Scraper

Compatible Products

FAQ

What Can You Use Serrated Utility Knife Blades For?

Serrated utility blades, in contrast to straight-edge blades, are ideal for any application that requires a sawing motion. Typically this includes tough, textured materials that benefit from the penetrating action of the teeth on a serrated edge. These teeth first puncture the exterior then saw through the interior. In the culinary world, the most common example is bread, where the hard crust must be punctured and the soft interior—which would otherwise collapse under the pushing motion of a straight-edge blade—can be sliced with a back-and-forth motion. In the industrial world, examples of materials that benefit from serrated utility knife blades include some types of textured foam and the tough strands that make up twine and rope.

How Are Slice Serrated Utility Blades Safer?

Slice safety blades feature our patent-pending finger-friendly® edge design. This is a proprietary way of grinding the blade with a double edge so that it cuts effectively but remains safe to touch. The double edge decreases the initial cutting zone and disperses the force of the cut across skin’s surface. Any blade can, of course, cut flesh with some effort, but Slice is the only company to manufacture a blade that’s both touchable and effective. Our serrated blades are no exception. Unlike traditional blades, which start out dangerously sharp whether they’re metal or ceramic, our blades start at a safe and sufficient sharpness. In contrast to metal, Slice blades maintain that safe level of sharpness for up to 11 times longer.

Are Slice Blades Breakable?

While ceramic is often considered an exceptionally fragile substance, it’s important to note that Slice blades are made from 100 percent zirconium oxide, an advanced ceramic that is in fact much harder than steel. This is part of the reason (along with our proprietary grind) that our blades last up to 11 times longer than comparable steel blades. It’s important, also, to have proper expectations about how our serrated utility knife blades are meant to be used. Like any other blade, they’re intended to withstand the downward force of slicing or cutting, but are not meant to be subjected to a side load. On occasion, our blade edges sustain microscopic chips (as do all blades), but this won’t affect their ability to cut. Slice blades are not meant to scrape against hard surfaces, like concrete.

How Long Do the Serrated Utility Blades Last?

Slice blades have been tested independently by a third party to determine how they compare with standard steel utility blades. The result was clear: our blades last up to 11.2 times longer than steel. Serrated blades also tend to last longer than straight blades, due to their notched edge; not all areas of the edge absorb the same amount of force as they would on a straight edge.

What Handles Are Compatible With the 10523 Blades?

Slice is committed to continuous innovation and always has several new tools in development. Our utility blades were created in conjunction with a customer to help improve the safety of their manufacturing process. While we found that the blade fit in some third-party handles, they didn’t fit in all. Rather than trying to accommodate a huge number of handles whose manufacture wasn’t in our control, we decided to create handles that were designed, from the ground up, to fit our straight and serrated utility knife blades. Both our manual and auto-retractable metal-handle utility knives are compatible with the Slice 10523, 10524, and 10525 utility blades.

How Do I Dispose of a Slice 10523 Blade?

The unique Slice finger-friendly edge doesn’t require special sharps box disposal, as do dangerously sharp traditional blades. Professional occupational safety experts must, of course, choose safety guidelines for any given workplace, but most do not require sharps box disposal for Slice rounded-tip blades. Our pointed-tip blades have the potential to pierce standard garbage bags, so we encourage companies to evaluate them and make their own determination regarding sharps disposal.

As with all Slice blades, our serrated utility blades are 100 percent recyclable—if no facilities exist in your area, feel free to ship your used blades to Slice’s headquarters in San Jose, California, where we’ll happily recycle them for you.

As with all Slice blades, our serrated utility blades are 100 percent recyclable—if no facilities exist in your area, feel free to ship your used blades to Slice’s headquarters in San Jose, California, where we’ll happily recycle them for you.