Translation missing: da.accessibility.faq_content_title

Hvad er en arbejdskniv?

Arbejdsknive, også kaldt hobbyknive, er håndværktøj, der bliver brugt til at skære pap, plast og andre indpakningsmaterialer. Det er et værktøj, der bruges på både hjemmefronten og i industrielle kontekster. De bedste af denne slags knive er udstyret med sikkerhedsforanstaltninger for at undgå stiksår - et perfekt eksempel er vores patentanmeldte finger-friendly® Slice® knivblade. Stiksår er en af de mest hyppige skader på arbejdspladser, men de kan let undgås.

Visse hobbyknive giver dig muligheden for, at vælge mellem forskellige fikserede bladpositioner, så du kan matche den nøjagtige dybde af det materiale, du arbejder med. Andre arbejdsknive har auto-indtrækkelige knivblade, der forhindrer de ulykker, der ofte finder sted, når kniven ikke er i brug.

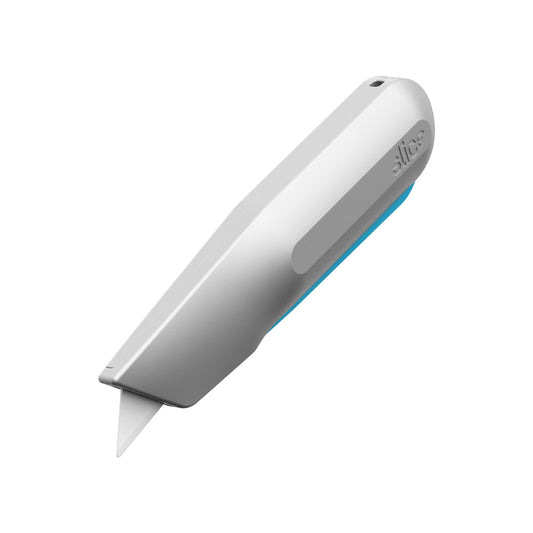

De fleste Slice-arbejdsknive giver dig muligheden for, at vælge mellem modeller, der enten er udstyret med manuel eller auto-indtrækning. Vores 10562 Foldbar Arbejdskniv kan foldes til at øge beskyttelsen af bladet. Vi tilbyder også den innovative 10558 Smart-indtrækkelig Arbejdskniv: Knivbladet trækkes ind, så snart der ikke er kontakt med materialet, der skæres i. Alt manuelt værktøj fra Slice kommer med adskillige positionsindstillinger til knivbladet, og alle auto-indtrækkelige modeller fra Slice inkluderer brug af velfunderet teknologier til at opnå denne sikre indtrækning af knivbladet.

Hvad bruges en arbejdskniv til?

Brugen af industrielle arbejdsknive rækker fra at åbne papkasser, skære i palleemballage, plastik, samt beskæring af råmaterialer på fabrikker. Som der antydes af navnet, er disse knive designet til at være slidstærke, samt til at fungere effektivt i mange forskellige kontekster.

Alle Slice-knivblade er lavet af zirconiumoxid, der er kemisk inaktivt, hvilket gør, at det aldrig ruster. De er også resistente overfor høje temperaturer. De forbliver egnet til brug helt fra -40 grader til 1600 grader Celsius. it remains structurally sound from -40 degrees to 1600 degrees, Celsius. Det er netop grundet denne egenskab, at knivblade lavet af 100 procent zirconiumoxid er perfekt egnet til brug i laboratorier eller under ekstreme forhold.

Er Arbejdsknive og Box Cutters det samme?

Alle arbejdsknive og box cutters fra Slice gør brug af vores unikke sikkerhedsknivblade og kommer med mange af de samme funktioner. Dog tilbyder de hver i sær forskellige håndtagsdesign og bladlængder.

Det korte knivblad hos en box cutter, såsom Slice Auto-Indtrækkelig Box Cutter, vores Manuel Pennekniv, eller vores Manuel Mini-kniv, åbner let emballage med minimal eksponering af knivbladet. Dette reducerer risikoen for skader til både krop og pakkernes indhold.

En Slice-arbejdskniv, om det er en af vores arbejdsknive med glasfyldte nylonhåndtag eller blot en af vores arbejdsknive med metalhåndtag, kommer den altid med et længere knivblad, og kan heraf skærer i et bredere sortiment af materialer. Hvis du skal skære dybe snit, tilbyder Slice også industriknive, der er udstyret med ekstra lange knivblade. De er perfekt egnet til at skære i bløde og tykke materialer, såsom skum eller glasfiberisolering.

Den bedste arbejdskniv eller box cutter til ethvert job, er den, der evner at skære effektivt uden at skære på sikkerheden.

Hvad får Slice-arbejdsværktøj til at skille sig ud?

Alle Slice-knivblade er lavet af 100 procent zirconiumoxid, hvilket er en avanceret keramiktype, der ikke kan ruste, er ikke-ledende, umagnetisk, samt gnistfri. Herefter påfører Slice dets patentanmeldte finger-friendly slibning til materialet. Det skaber et knivblad, der skærer effektivt uden at skære på sikkerheden.

Stålblade er utrolige skarpe, når de er helt nye. Dette er grundet, at de mister deres skarphed relativt hurtigt. Når knivblade enten er for skarpe eller for sløve, er det netop dér, at de er allermest farlige. Et alt for skarpt knivblad formår let at forårsage stiksår. Med et sløvt knivblad, er brugeren nødt til at bruge ekstra kræfter for at skære effektivt, hvilket betyder, at chancerne for at miste kontrol over kniven stiger.

Zirconiumoxid er ekstremt hårdt, og i sammenspil med Slice’s patentanmeldte design, holder vores knivblade op til 11 gange længere end stål. Dette betyder at værktøj, såsom Slice 10554 Auto-indtrækkelig Arbejdskniv eller vores 10490 Manuel Arbejdskniv Med Metalhåndtag levere en effektivt og konsistent skæreevne, der udkonkurrerer andre stålknive, når det kommer til holdbarhed. Færre bladskift og et vendbart (dobbeltsidet) knivblad sænker omkostningerne mht. vedligeholdelse drastisk.

Traditionelle keramikfrabrikanter forsøger at efterligne det utrolige skarpe design, der er så populært blandt metalblade, og derfor forårsager keramiske knive stiksår lige så ofte. Når det kommer til fordelene ved keramik, skal det siges, at ikke alle keramiske knivblade er udgjort af den samme komposition af materialer, hvilket betyder, at knivenes præstationer kan variere fra fabrikant til fabrikant.

Valgmuligheder af Knivblade til Slice-Arbejdsknive

De forskellige værktøj, vi har gennemgået indtil videre, fragtes med et knivblad, der har en dobbeltkant og en afrundet spids. Alle disse værktøj er også kompatible med vores udskiftelige knivblade, der har en skarp spids.

I øvrigt laver Slice også udskiftelige savtakkede knivblade, der passer perfekt til vores arbejdsknive med metalhåndtag (10490 og 10491), samt vores industriknive (10559 og 10560).

Bladet du vælger, afhænger af hvordan du ønsker at bruge værktøjet. Knivblade med afrundet spids beskytter dig mod eventuelle punkteringer og kan håndtere de fleste former for materialer. Knivblade med skarp spids, skal bruges i tilfælde hvor du skal penetrere et materiale før du kan begynde at skære. Et savtakket knivblad fungerer bedst til opgaver, hvor det kræver, at du saver i materialer.

Penneknive, mini-knive og box cutters fra Slice bruger alle sammen de samme knivblade, netop knivblade til box cutters. Vores Foldbar Arbejdskniv og glasfyldte nylon arbejdsknive gør begge brug af vores knivblade til arbejdsknive. Industriknivene har deres helt egne bladmodeller (Industrielle Knivblade). Det har vores arbejdsknive med metalhåndtag også. De bruger vores velkendte trapezformede knivblade til arbejdsknive.

Håndtag designet med henblik på holdbarhed, sikkerhed og brugbarhed

Arbejdsknive og box cutters fra Slice har håndtag, der er lavet ud af enten metal eller holdbart glasfyldt nylon (GFN), så de er egnet til industrielt brug.

Slice-box cutters har et J-formet håndtag, der let hægter sig fast på lommer, så knivbladet holdes langt væk fra kroppen. Vores mini-knive, box cutters, arbejdsknive med GFN-håndtag, samt vores penneknive, er alle sammen udstyret med et lanyard-hul, der kan bruges til let opbevaring af ens arbejdskniv, når den ikke er i brug. Håndtaget på Slice-mini-kniv er også magnetiseret, hvilket giver endnu en mulighed for let at kunne opbevare den sikkert. Vores foldeknive er udstyret med et smart bæltespænde.

Alle Slice-arbejdsknive kan bruges af både venstre- og højrehåndet.

Hvilke valgmuligheder har Slice-arbejdsknive mht. kontrol?

Slice-værktøj tilbyder mange forskellige muligheder, når det kommer til kontrol: manuel indtrækning, auto-indtrækning og smart-indtrækning. Med vores foldbare knive kan man selvfølgelig folde knivbladet tilbage, når det skal opbevares. Produkter såsom vores Manuel Industrikniv har en skydeknap, der kan sætte bladet i en ud af mange forskellige positioner, hvor vores Auto-indtrækkelig Pennekniv er en tilbagetrækkelig arbejdskniv: knivbladet trækkes tilbage, når brugeren giver slip på skydeknappen. Vores Slice 10558 Smart-indtrækkelig Arbejdskniv har en innovativ funktion, der muliggør, at bladet trækkes ind automatisk, når det ikke har kontakt med noget materiale, selvom brugerens hånd stadig er på skydeknappen. Denne funktion hjælper med at undgå skader, hvis man mister kontrol over kniven.

Hvad betyder Ergo-Pull?

Slice’s Ergo-Pull™ teknologi blev introduceret sammen med vores 10558 Arbejdskniv. Mens vi genovervejede alle designets aspekter, tog vi også et kig på den ergonomiske indflydelse af skydeknappen, der bruges til at skyde knivbladet ud, som brugt i mange klassiske mekanismer af den slags. Det vi opdagede var, at selvom de fleste skydeknapper kræver at man skubber med fingeren, er det mere ergonomisk at hive fingeren tilbage for at aktivere bladet.

Prøv at tænk på det sådan her: Når du skærer med kniven, hiver du allerede kniven mod dig selv. Dette betyder, at hvis du skal skubbe til skydeknappen på samme tid, spænder du din hånd unødvendigt. Men hvis du i stedet hiver knappen tilbage på samme tid, føles det langt mere naturligt. Hvis vi så tager den et skridt videre, resulterer denne metode i, at skydeknappens position skaber et langt mere balanceret greb. Traditionelle designs tvinger brugerens hånd ind i et akavet greb.

For at teste effektiviteten af vores nye design, hyrede Slice US Ergonomics tilbage i September 2016 til at udføre nogle sammenligninger mellem vores 10558-værktøj og et typisk (ikke-Slice) kniv med en skydeknap, der skubbes. Hvad var deres konklusion?

“Brugen af Slice [Ergo Pull] resulterede i lavere belastning af både hånd og håndled i forhold til en standard arbejdskniv med skydeknap, der skal skubbes”

Hvis du ønskere flere detaljer om vores ergonomiske teste, kan du checke vores FAQ: Hvordan ved jeg, at Slice-værktøj er mere ergonomiske?

Hvad gør jeg, hvis jeg skal udføre komplekst arbejde i et trangt område?

Slice laver et stort udvalg af håndtag, der vi er bevidste om det store antal af forskellige anvendelser og præferencer, der findes ude i verdenen. Vi ønsker at vores kunder findes det Slice-værktøj, der passer allerbedst til deres givne opgave. Nogle specialopgaver kræver styrken, der tilbydes af en af vores arbejdsknive, men samtidig et værktøj, der kan bruges i snævre områder eller et værktøj, der tilbyder ekstra kontrol end hvad standard Slice-knive tilbyder.

Hvis du står overfor specialopgaver, der kræver skæreværktøjer, der egner sig til snævre områder, så bør du tjekke vores Præcisionsknive-kategori. Disse knive tilbyder en høj grad af kontrol, samt et smaller håndtagsdesign. Knivbladene, der kommer med disse præcisionsknive, er smaller end mange af de knivblade, vi har fremvist her. De er dog stadig lige så stærke og kommer med alle de samme fordele. Hvis du ønsker et knivblad, der er endnu mindre, så bør du overveje vores Keramiske Skalpeller. Disse knive er perfekt egnet til komplekse opgaver i snævre områder, hvor de lidt større arbejdsknive klarer sig bedst til større industrielt brug.